The Futuristic Building Materials Fighting Carbon Emissions – What We’re Excited About in 2026

The building industry has a carbon problem. According to the 2024–2025 Global Status Report for Buildings and Construction by UNEP / GlobalABC, the building and construction sector accounts for about 34% of global CO₂ emissions and roughly 32% of energy use. These numbers can feel like a daunting challenge, but challenges can be opportunities for innovation.

While there are many architectural and interior design strategies involved in low and negative carbon buildings, building materials and finishes are common opportunities for carbon reduction. To illustrate the variety of low-carbon offerings that the materials industry offers, we've compiled some new, cutting-edge products and services we’ve found that make it easier to reduce a construction project’s carbon footprint. From reclaimed doors to lamps made from fungi, there’s never been more options to start building with sustainable materials in mind.

Fungi-based Materials

Mycelium is the root-like network of fungi and is one of the most abundant natural organisms on Earth. While it’s usually hidden from view, mycelium is everywhere, quietly transforming organic matter. In recent years, researchers and manufacturers have developed ways to grow mycelium into durable, lightweight, and biodegradable materials.

MushLume Lighting is a “biofabricated” lighting collection that uses mycelium and sustainably sourced hemp, creating beautiful and minimalist lighting products. Mycelium is used as a binder to hold the material together, essentially growing the products in place.

This living design process gives each piece a uniquely organic look, creating practical lighting for sustainable spaces. Additionally, all pieces are UL Certified and ASTM E84 - 2025 Grade “A” fire rated, and they are currently being used in both commercial and residential applications.

okom wrks labs is San Diego-based lab developing zerø-frm, a structural mycelium product designed for interior and exterior walls, insulation, cladding, and sheathing. Though not yet commercially available, the lab claims their patent-pending composite is 1000% stronger than existing mycelium products and could one day rival mass timber. If these claims are independently verified and the product comes to the market, zerø-frm could transform the industry with a renewable, carbon-storing material grown from fungi.

Hemp Materials

Hemp has been cultivated for thousands of years for manufacturing ropes, textiles, and other durable products. Today in the U.S., it is gaining renewed attention as a construction material.

Hempcrete, a mixture of hemp’s woody core and a lime-based binder, has been used in France since the early 1990s. Unlike cement-intensive concrete, hempcrete can be carbon-storing, and has been shown to be carbon-negative in some studies depending on mix, sourcing, and boundaries. Hemp plants absorb CO₂ during growth, and the lime binder continues sequestering carbon over time.

Author: Romancito77 | Creative Commons Attribution-ShareAlike 4.0 International

The material offers excellent thermal and acoustic performance, regulating humidity and providing natural insulation. It’s also fire-resistant, pest-resistant, and highly durable, making it attractive for both residential and commercial applications. While hempcrete is not a structural replacement for reinforced concrete or steel, it can be used as infill for walls, insulation, and non-load-bearing construction.

Manufacturers like American Lime Technology and IsoHemp are creating a new generation of insulations and masonry materials made from hemp and lime. If demand continues, hempcrete could become a part of the broader toolkit for reducing the building industry’s massive carbon footprint while promoting local agriculture.

Reused and Recycled Materials

Sometimes reducing carbon can mean recycling existing material waste into new products. Rather than relying on virgin raw materials, upcycled or downcycled materials give new life to what would otherwise end up in landfills.

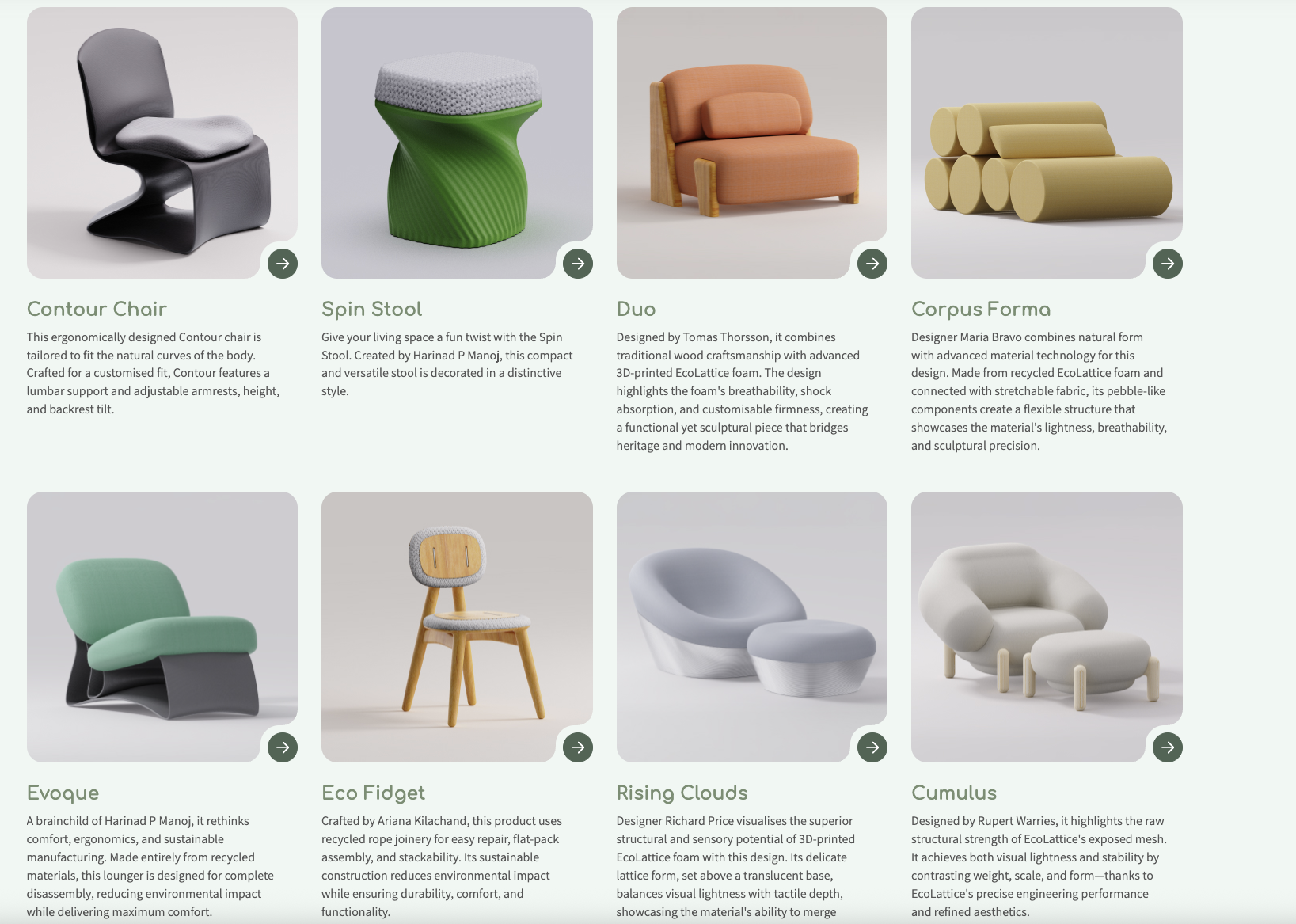

Eco Lattice, a recycled materials company, is redefining sustainability by combining recycled thermoplastic elastomers (TPEs) with advanced 3D printing / lattice structuring. The manufacturing process aims for zero waste, and the company advertises the material being used for seating and lamps that furnish a room for little to no carbon cost.

Screencap from Eco Lattice website on January 6, 2026

Doors Unhinged offers products marketed as zero-carbon and prioritizes reclaiming materials that are marked for demolition, removing doors and frames from buildings before they are destroyed. Doors Unhinged claims that their products can cost up to 50 percent less than a brand-new door package, due to their use of these low-cost waste materials. They also significantly reduce the carbon cost of these materials in the building process and reduce landfill waste.

At Neumann Monson, we’re excited by opportunities to design reuse into our projects. When remodeling our Iowa City studio, we prioritized reclaimed materials. All doors and ceiling tiles were reused, along with 99% of the glass and 76% of casework. This experience highlights a key principle: sometimes the most innovative solution comes from reclaiming and reimagining what already exists.

Want to Try Sustainable Design in Your Next Project?

These products are just a few examples of useful innovations that can reduce the environmental impact of construction projects and provide sustainable benefits to owners. But if you want to expand the scope of sustainability to an entire facility, you’ll likely need the assistance of an architect.

If you’re interested in a sustainable design for your next project, schedule a meeting with our architects to see the benefits of sustainability and explore options that fit your vision and budget. For inspiration, look no further than our Stanley Center case study, a project that puts sustainability at its core.

(The manufacturers featured in this article are not officially endorsed by Neumann Monson Architects and are provided as examples only. We encourage you to research any company before purchasing goods or services.)