Using Urban Lumber on a Building Project

Trees are an invaluable urban resource. They shade our streets, protect our homes, and beautify our communities. Every tree has a story spanning decades—and that story shouldn’t have to end after the tree’s removal.

Whether due to disease, storm damage, or right-of-way needs, cities remove trees for various reasons. Urban lumber programs give these trees a new life, saving them from woodchippers and putting them to good use.

During our Iowa City studio renovation, we worked with Koffron Hardwoods, McComas-Lacina Construction, and the cities of Iowa City and Coralville to use urban lumber for workstations, casework, and wall panels. In our experience, using urban lumber is a cost-effective way to reduce your carbon footprint, support local businesses, and tell a larger story about your community.

This article will discuss urban lumber, its benefits, and some considerations when using this resource.

What is Urban Lumber?

Urban tree removal is a common sight. While some trees are taken down due to disease or storm damage, others block development or powerlines. Typically, these trees become firewood or mulch. Occasionally, they end up in the landfill.

Such practices can be costly, with municipalities often losing money mulching. They are also wasteful. While portions of a tree are best converted into wood chips and mulch, most trunks can be lumbered.

Urban lumber programs help reduce waste and make better use of this resource by connecting people along the supply chain, including sawmills, woodworkers, and business owners. In Iowa, the Department of Natural Resources forestry program champions urban lumber use, and the practice is gaining popularity in cities like Iowa City and Des Moines.

In Coralville, Iowa, trees damaged by the 2020 derecho were repurposed into a boardwalk for the Clear Creek Greenbelt. Area homeowners have even used fallen or damaged trees from their yards for furniture, cabinets, flooring, and trim.

When renovating our Iowa City studio, we used ash wood from Iowa City and Coralville. The Emerald Ash Borer, an invasion insect, has decimated the ash tree population across the Midwest.

In our Iowa City studio, we used urban ash for cabinets, tables, and workstations.

Although the situation is unfortunate, we saw an opportunity to give these trees a new life. As one of our team members suggested during the design process, we might as well use the wood that is already being removed.

Benefits of Urban Lumber

1. Connection to Place

Urban lumber offers many benefits. First, it is highly localized, with lumber coming from trees in your community.

This approach can connect your project to its place and tell a more meaningful story than lumber shipped from another location. Some owners even take a hyperlocal approach by using lumber directly from their building site for furniture and finishes.

2. Sustainability

Urban lumber is also more sustainable, reducing the carbon emissions associated with transportation. All new lumber in our Iowa City studio came from trees within ten miles of our studio. After milling and assembly, the lumber traveled less than 40 miles before arriving on the site.

Similarly, using urban lumber reduces the carbon emission released by burning or mulching. Wood sequesters carbon, and when it’s destroyed, the carbon returns to the atmosphere. Reusing trees that would otherwise release carbon is a simple and direct sustainability strategy.

Most trunks can be lumbered, saving them from woodchippers.

Urban lumber is also a better option from a material health perspective. Compared to engineered wood products—like particle board and Medium Density Fiberboard (MDF)—hardwood products are more natural and less energy-intensive.

Creating engineered wood uses significant amounts of chemicals and adhesives. Solid urban lumber, on the other hand, requires minimal glue to laminate edges and make larger pieces.

3. Supporting Local Business

From a cost standpoint, urban lumber is usually more affordable than commercial lumber, especially when removed trees are in high supply. Although lumber costs may be lower, labor costs may be slightly higher.

Depending on your needs, you will most likely work with local millers and craftspeople to create a customized product. Generally, this is more expensive than an off-the-shelf composite wood product.

While labor costs may be higher, you are supporting local businesses. Whether a home remodel or commercial building project, incorporating urban lumber is a great way to build community connections.

4. Strength and Character

Urban lumber benefits from slow growth. Unlike most commercial lumber, urban lumber has developed over decades or centuries, withstanding wet and dry periods. This slow growth can add more strength and character, with more grain pattern variations than commercially grown wood.

Urban lumber can give you access to more grain patterns and variations.

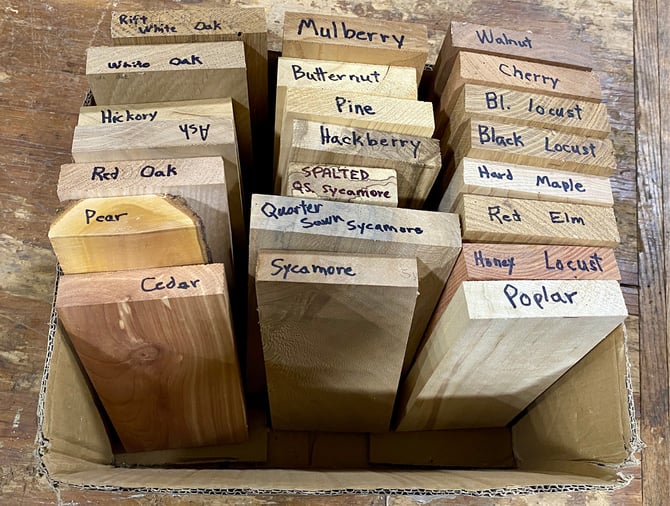

Using urban lumber may also give you access to more unique lumber types. Cities contain diverse ecosystems, with unique species like hackberry, locust, and sycamore in parks and yards. This large variety creates a wider selection of color, grain pattern, and hardness than you may receive otherwise.

Urban lumber can provide access to a greater variety of wood types.

Compared to engineered products, natural wood is more durable. It is less prone to damage than wood veneers and can be sanded and refinished dozens of times. In the end, you receive a longer-lasting product.

Considerations When Using Urban Lumber

When using urban lumber on a building project, there are a few considerations to remember.

Depending on your needs, you may need to account for drying times. The lumber may not be available immediately, and you may need to wait for products to arrive on-site. Your design team should have experience working with material lead times and set realistic expectations.

At the same time, urban lumber can only be used for furniture, flooring, cabinetry, and other interior finishes. Building codes specify grade-stamped lumber for structural purposes, limiting urban lumber’s use.

Like all hardwood products, urban lumber is likely to expand and contract. It may change throughout the year, depending on humidity levels.

For some, the changing nature of hardwood is a benefit, adding character. Others may prefer something more uniform, opting for MDF and wood veneer. Your design team should help you weigh the pros and cons of each option.

Lastly, urban lumber may have some flaws. Occasionally, urban lumber contains imperfections from nails or metal stuck in the wood. Diseased trees—like those affected by the Emerald Ash Borer—may have grooves or divots.

Once again, this may be a benefit. Leaning into imperfections can tell a larger story about the tree and your community. If you desire a more finished and uniform look, the fabrication team can work to hide blemishes.

See Urban Lumber in Action

Urban lumber programs help utilize dead, dying, or diseased trees. Often, these trees have developed over decades or centuries, and we should find ways to put them to good use. In addition to repurposing a valuable local resource, using urban lumber can lower your carbon footprint, support local businesses, and create a more impactful, meaningful project.

If you are interested in using urban lumber for your personal projects, we recommend contacting your local forestry or parks department. Ask them if they work with local sawmills and determine if any lumber is available for purchase. If starting a building project, your design team can walk you through this process and contact the necessary parties.

In our experience, urban lumber helped us meet the material requirements for CORE certification. To learn more about the certification and see urban lumber in action, read about our Iowa City studio renovation.