Mixing Construction Types: Podium and Wrapper Buildings

For commercial and residential developers, higher-density, mixed-use buildings present many practical benefits and opportunities. Integrating retail, living, work, and entertainment into a cohesive package, the approach can maximize development and activate urban areas with various tenants.

Despite the benefits, higher-density buildings present some risks and challenges. While all structures are subject to the International Building Code (IBC), requirements increase with height and density, as well as initial costs and construction complexity. To manage risk, owners and developers should understand these regulations and take advantage of more recent developments in the building code.

One approach is mixing construction types. These building types—including podium and wrapper buildings—mix Type I Construction with another type to address parking needs while providing fire separation for different uses.

At Neumann Monson, we have designed numerous projects that mix construction types, including podium buildings like Hieronymus Square in Iowa City and One University Place in University Heights. The Sabin Townhouses in Iowa City illustrate a wrapper approach, and 111 East Grand in Des Moines is a mass timber building lining a parking garage. Each project demonstrates a different approach to separating uses.

In this article, we will outline the five construction types established in the IBC to help you understand the differences and nuances. We will also discuss how to mix construction types and make the building code work for your budget and goals.

Construction Types in the IBC

Chapter Six of the IBC outlines five types of construction—classified by Roman Numerals I through V. According to the IBC, the purpose of classifying buildings by construction types is to account for the fire-resistive properties of building elements, the location a fire might originate, and the number of occupants.

This section of the IBC guides the use of materials, a building’s allowable height and area, occupant density, and the separation/protection of uses. It sets standards for major building elements, including structural systems, floors, walls, and the roof.

Generally, the taller the building, the greater the fire resistance. While Type I is the most fire-resistive, Type V is the most combustible. For materials, concrete, masonry, and steel provide the highest fire resistance while wood provides the lowest.

Type I, II, and II are subdivided into categories “A” and “B” to specify different levels of protection for structural elements. For example, Type I-A requires higher fire-resistive properties for structural elements than Type I-B. Type IV has three subcategories—IV-A, IV-B, and IV-C—that were updated in 2021.

Due to these requirements, a building’s construction type impacts its cost, complexity, and construction methods. Types I and II have the highest initial costs, while Types III, IV, and V tend to be at the lower end of the spectrum. Similarly, Type I accommodates more occupants while Type V accommodates the fewest.

Properly classifying a building’s construction type helps ensure requirements are not overly restrictive or costly for an owner.

Type I

In addition to other buildings requiring the highest degree of fire protection, Type I applies to high-rises—buildings 75 feet or higher above the lowest level of fire department access. These buildings must withstand high temperatures for long periods of time to allow occupants to exit in an emergency.

Type I Construction applies to high-rises, like Park@201 in Iowa City.

Its requirements apply to the building’s structure, load-bearing walls, floors, roof, demising walls between different uses and living spaces, and exit pathways like stairs and elevators. Accepted materials include reinforced concrete and fire-protected steel. Generally, these materials are the costliest and require specialized labor.

Type I-A construction allows for the greatest height while Type I-B is appropriate for mid-rise buildings and mixed-uses. I-B’s slightly lower fire rating requirements tend to be appropriate for structures like apartment buildings and hotels.

Type II

Type II construction refers to buildings that use non-combustible materials like exposed steel. Unlike Type I construction, fire-protective coatings are not required, though fire sprinkler systems are necessary. This construction type is appropriate for lower-height buildings, including schools and commercial developments like shopping malls.

Type III

Often called “ordinary construction,” Type III consists of buildings with non-combustible exterior walls made from brick, masonry, concrete blocks, or precast panels.

While exterior walls are non-combustible, interior elements and the roof may use wood-frame construction. The goal is to contain fire within the walls and prevent it from spreading to other buildings.

Type IV

Type IV construction is also known as “heavy” or “mass timber construction.” As the name suggests, it refers to buildings with large, structural wood (engineered or natural) columns, beams, and floor panels with bolted and plate metal connections.

111 East Grand, a mass timber building in Des Moines.

From a fire safety perspective, heavy timber members take a long time to burn. As it burns, the timber develops a char, providing insulation and protection from further damage. As such, this construction method is more resistant to collapse than lighter wood-frame construction.

A 2021 update to the IBC expanded the allowable area and heights of mass timber construction. While Type IV-A addresses fully protected construction, IV-B allows some level of exposed surfaces. Type IV-C relies solely on the fire-resistive properties of the wood.

Type V

Generally, Type V refers to light wood-frame construction. This type of construction has the lowest cost and requires the least amount of construction expertise, making it popular with self-performing developers.

However, for fire safety, Type V construction is the most combustible and prone to collapse, limiting its use to buildings with lower occupant numbers.

Type V-A is referred to as “protected frame construction” and is a common approach to smaller multifamily design. Type V-B, on the other hand, is known as “unprotected frame” construction and is typical for single-family homes.

Mixing Construction Types

In recent years, mixing construction types has become a more common practice. A 2012 update to the IBC allows developers to mix Type I construction with another type in specific cases.

This change means owners and developers can build larger structures—typically under 85 feet—without the cost and complexity of using Type I construction for the entire building. Below, we’ll discuss two building types that demonstrate the benefits of this approach: podium and wrapper buildings.

Podium Buildings

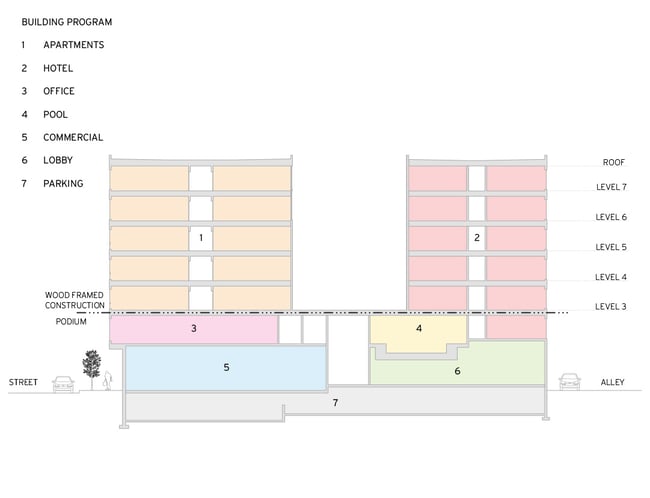

Podium buildings—also called Pedestal or Platform buildings—refer to structures consisting of a one- or two-story Type I base topped with four to five stories of another construction type, typically Type III or V (wood).

Essentially, it is two buildings stacked together and combined visually. Lower commercial levels tend to be concrete, while upper residential units are wood framed. Often, podium buildings contain below-grade parking.

A podium building combining Type I and wood-framed construction.

For fire protection, a horizontal concrete slab separates the lower podium levels from the floors above. Fire sprinkler systems are required, and fire-rated shafts extend vertically through the building to protect stairs, elevators, ductwork, and piping.

This building type offers many benefits. For one, it helps lower construction costs while increasing density. While a specialized contractor may need to complete the lower-level podium, some developers may be able to self-perform work on the upper floors.

Hieronymus Square, a podium building in Iowa City.

The concrete podium also allows for wider spans, higher ceilings, and more inviting ground-level retail spaces—making the development more attractive to pedestrians and street life. Some developers also incorporate residential amenities—including indoor pools, fitness centers, and parking—into this portion of the building since the more robust construction can accommodate loading and acoustic needs.

Wrapper Buildings

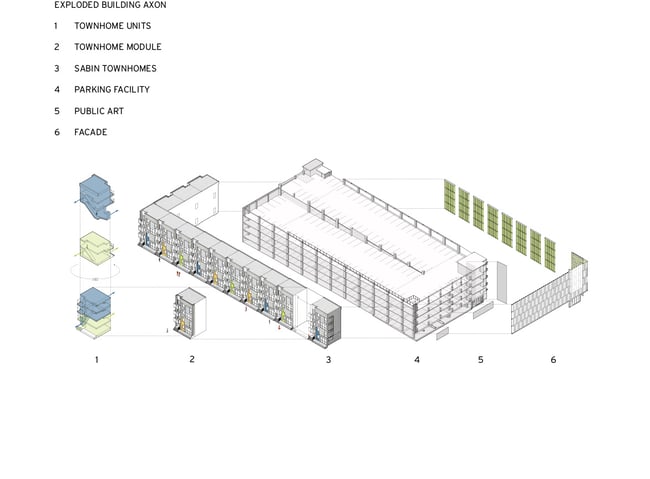

Wrapper buildings are another way to increase density by mixing construction types. Sometimes called “donut buildings” or “liner buildings”, these structures contain a Type I parking facility surrounded by commercial or residential buildings, typically Type III, IV, or V construction.

This approach allows developers to maximize the use and revenue of a site otherwise dominated by a parking structure. Wrapping or lining a parking structure with functional space increases density and presents a more aesthetically pleasing urban experience. Like podium buildings, developers can self-perform the work on the commercial/residential buildings, lowering costs.

A wrapper building with townhouse units surrounding a parking structure.

When designing a wrapper building, fire safety is key. One approach is to separate the commercial/residential building from the parking structure by at least ten feet. At this distance, the parking structure is considered open, eliminating the need for fire sprinklers and mechanical ventilation.

This approach was taken at 111 East Grand in Des Moines. With this project, a mass timber building lines the East 2nd Street Parking facility but remains a separate structure. While providing the look of a wrapper building, it lowers prescriptive requirements.

Another option is to separate the commercial/residential building from the parking structure with a fire-resistant wall. This approach—taken with the Sabin Townhouses—works well for a site with a tighter footprint. However, when taking this route, the parking structure requires sprinklers and mechanical ventilation.

Learn More About Mixed-Use Development

Although high-density buildings offer many benefits for urban developers, they can increase the cost and complexity of a construction project.

Mixing construction types is one approach to lowering this complexity while maximizing your return on investment. When planning a podium or wrapper building, an architect can help you understand the code requirements and ensure you meet fire and life-safety regulations.

Podium and wrapper buildings tend to be mixed-use, combining retail, commercial, and residential units into one structure. When done correctly, these developments can help create vibrant neighborhoods while diversifying revenue streams for developers. Learn more by reading our tips for planning a mixed-use development.